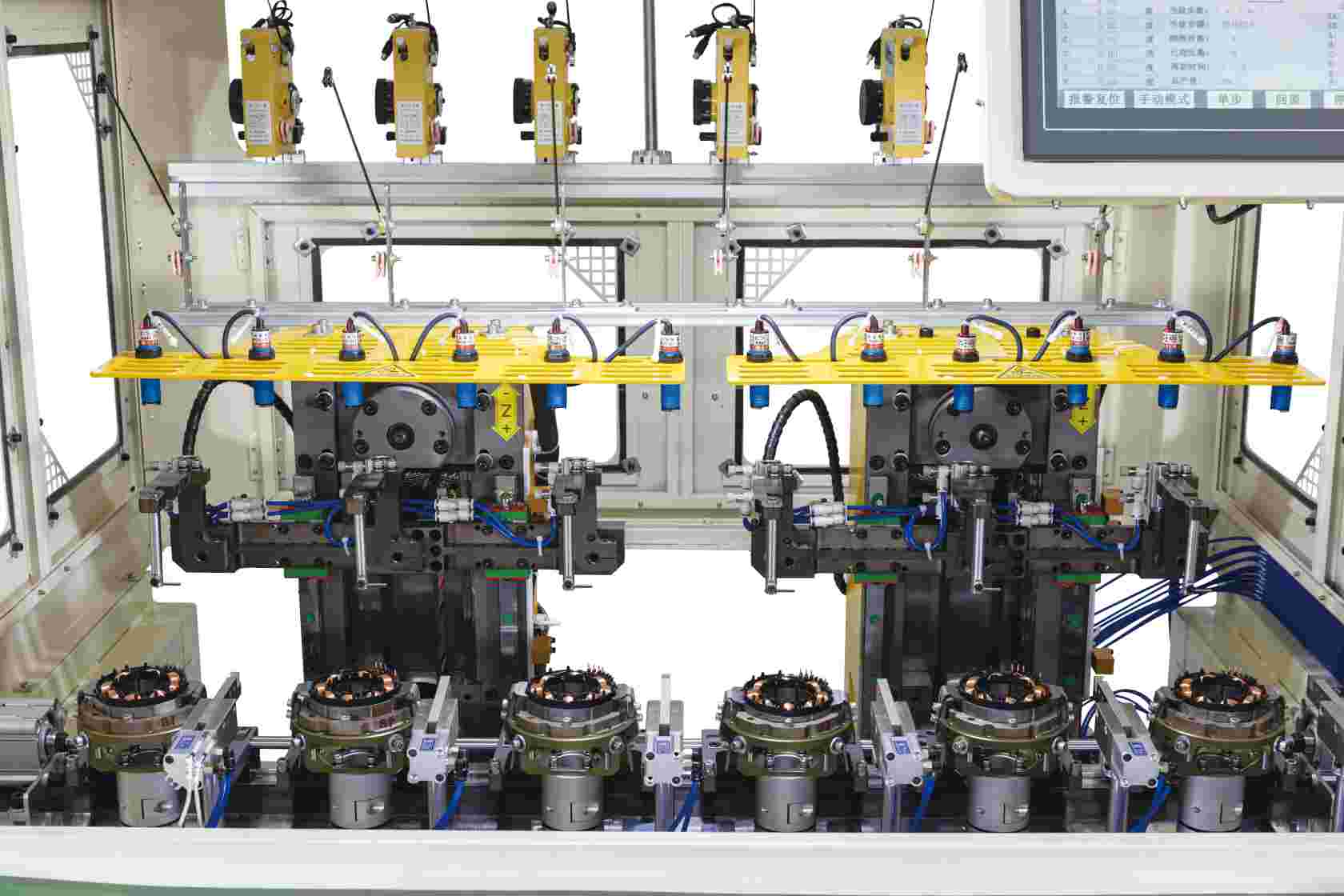

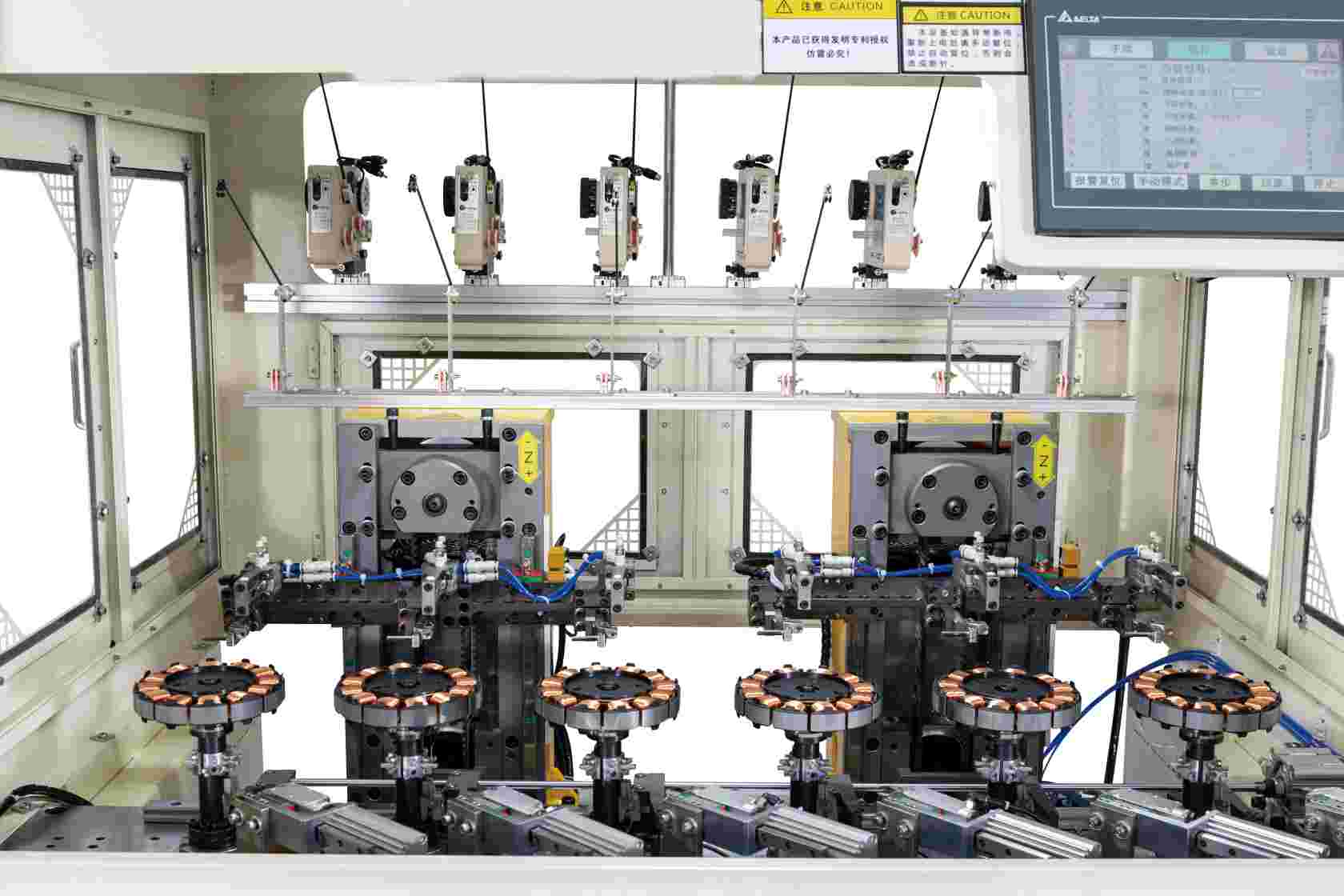

Six-Station Inner Winding Machine

Product Characteristics

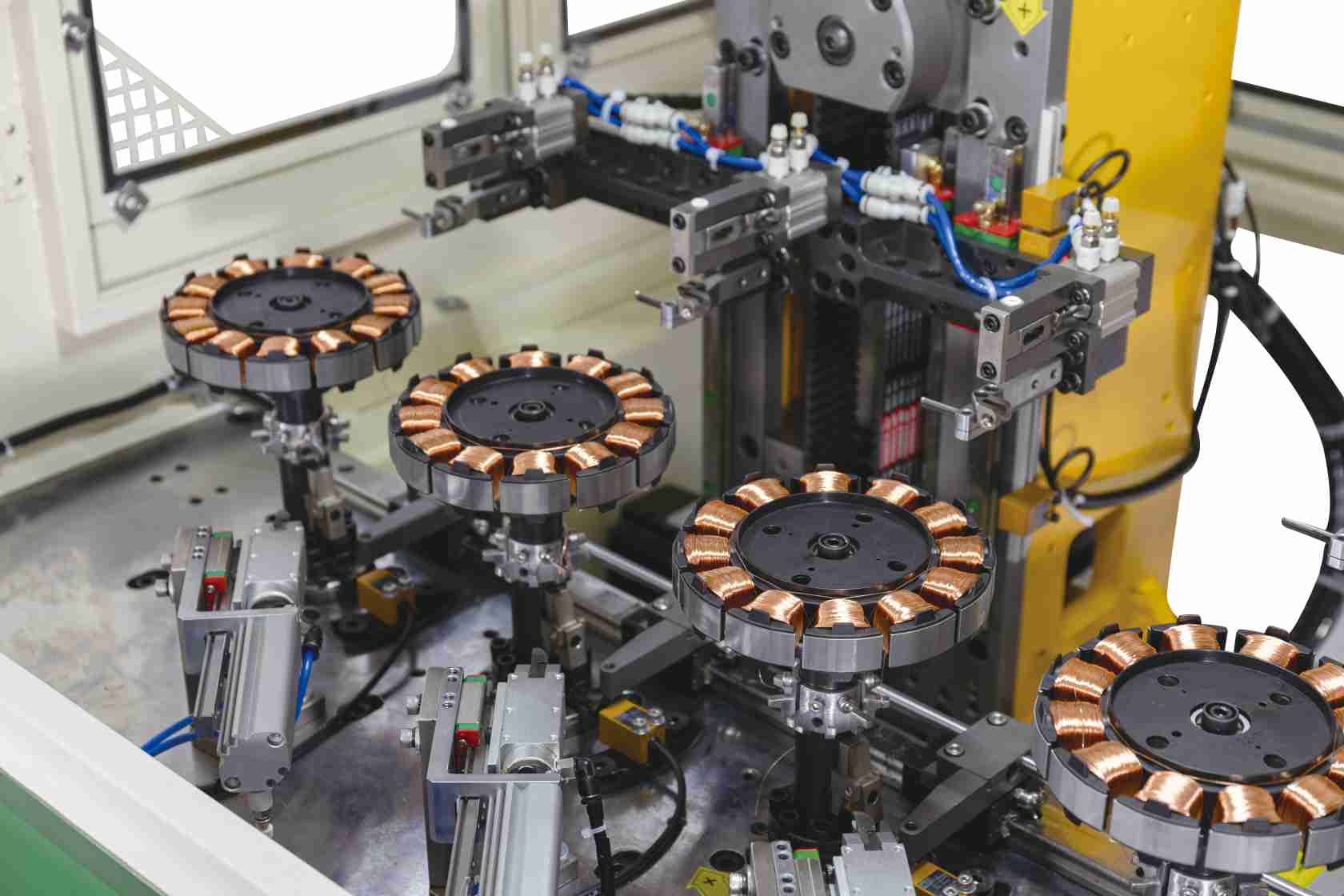

● Six-station inner winding machine: six positions are working at the same time; fully open design concept, easy debugging; widely used in various domestic brushless DC motor manufacturers. Normal operating speed is 350-1500 cycles per minute (depending on stator thickness, coil turns and line diameter), and the machine has no obvious vibration and noise.

● It adopts six-position design and precise servo positioning. It can automatically clamp the stator, automatically wrap the thread head, automatically wrap the thread tail, automatically wrap the wire, automatically arrange the wire, automatically rotate the position, automatically clamp and shear the wire, and automatically release the mould at one time.

● The man-machine’s interface can set the number of winding coils, winding speed, winding direction, stator rotation angle, etc.

● The system has the function of state display, fault alarm and self-diagnosis. With electronic tensioner, the winding tension can be adjusted and the broken wires can be automatically detected. It has the functions of continuous winding and discontinuous winding.

● The mechanical structure design is reasonable, the structure is lightweight, the winding is fast and the positioning is accurate.

● With the configuration of 10 inch large screen, more convenient operation; support MES network data acquisition system.

● Its merits are low energy consumption, high efficiency, low noise, long life and easy maintenance.

● The machine is a high-tech product with 10 sets of servo motor linkage, and a high-end, advanced and superior winding equipment is built on the advanced manufacturing platform of Zongqi Company.

Product Parameter

| Product number | LNR6-100 |

| Number of working heads | 6PCS |

| Operating station | 6 stations |

| Adapt to the wire diameter | 0.11-1.2mm |

| Magnet wire material | Copper wire/aluminum wire/copper cladaluminum wire |

| Bridge line processing time | 2S |

| Adapt to the stator stack thickness | 5mm-60mm |

| Minimum stator inner diameter | 35mm |

| Maximum stator inner diameter | 80mm |

| Maximum speed | 350-1500 circles/minute |

| Air pressure | 0.6-0.8MPA |

| Power supply | 380V three-phase four-wire system 50/60Hz |

| Power | 18kW |

| Weight | 2000kg |

Structure

onditions required for custom motor stator automatic line

A reliable custom motor stator automatic line should have high output and stable and reliable product design and process, which will remain unchanged for a long time. Using motor stator automatic lines in mass production can benefit businesses in many ways. They can increase labor productivity, stabilize product quality, improve labor conditions, reduce production floor space, reduce production costs, shorten production cycles, and ensure the balance of the production process.

The motor stator automatic line does not require any human intervention or instruction to program automatic operation or predetermined control process. They are designed to achieve stable, accurate and fast production results. Furthermore, their implementation frees workers from heavy physical labor, increases labor productivity and ultimately improves people's ability to understand and transform the world around them.

Electric motors play a vital role in mechanical movement and are present in our daily lives. With the rapid development of industry, it is becoming more and more important to find high-precision, miniaturized, low-speed motors suitable for the needs of various industries. The mechanical system of the motor determines the quality of the high-precision motor. High-speed and accurate motor positioning information technology is a necessity for many industrial controllers. With the vigorous development of the electronic equipment manufacturing industry, the professional development of industrial machinery automation has become a future trend. Therefore, there is an increasing demand for high-precision motors that meet the stringent requirements of mechanical motion.

Guangdong Zongqi Automation Co., Ltd. specializes in manufacturing motor manufacturing equipment. As an enterprise integrating R & D, manufacturing, sales and after-sales service, the main products are four-head and eight-station vertical winding machine, six-head and twelve-station vertical winding machine, embedding machine, winding embedding Machine integrated machine, binding integrated machine, rotor automatic line, shaping machine, vertical winding machine, slot machine, binding machine, motor stator automatic line, single-phase motor production equipment, three-phase motor production equipment. Customers who need such equipment are welcome to inquire about their products and services.