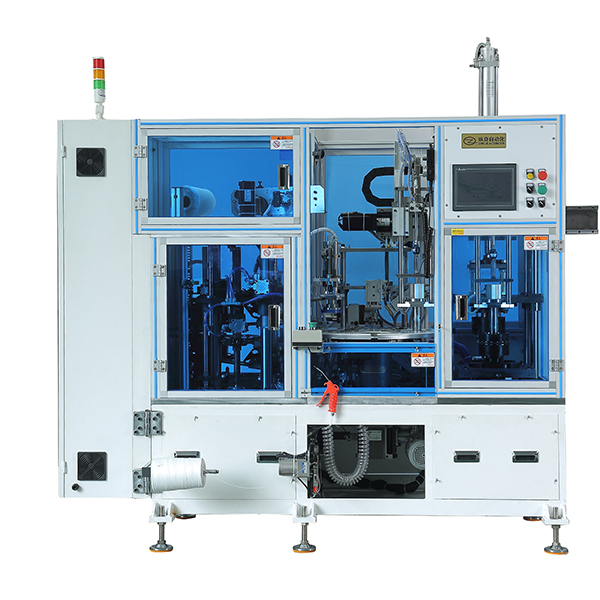

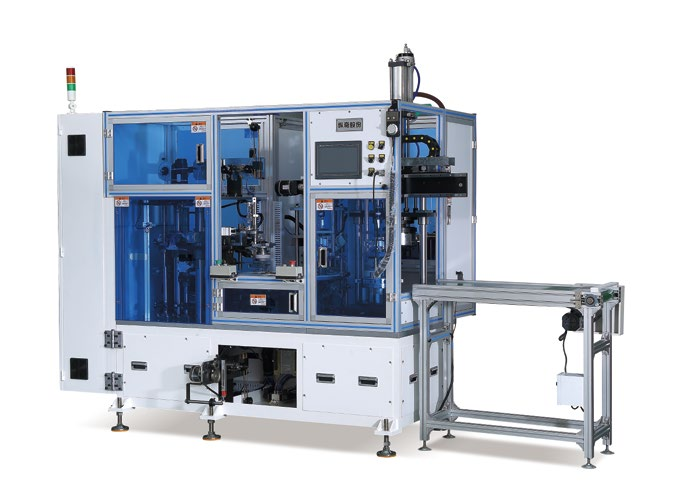

Professional Four-Station Binding Machine for motor manufacturing

Product Characteristics

● The machine adopts a four-station turntable design; it integrates double-sided binding, knotting, automatic thread cutting and suction, finishing, and automatic loading and unloading.

● It has the characteristics of fast speed, high stability, accurate position and quick mold change.

● The machine is equipped with automatic stator height adjustment, stator positioning device, stator compression device, automatic wire feeding device, automatic thread trimming device, and automatic wire break detection device.

● Using the unique patented design of the double track cam, it does not hook the grooved paper, does not hurt the copper wire, lint-free, does not miss the tie, does not hurt the tie line and the tie line does not cross.

● The hand-wheel is precision-adjusted, easy to debug and user-friendly.

● The reasonable design of the mechanical structure makes the equipment run faster, with less noise, longer life, more stable performance, and easier to maintain.

Product Parameter

| Product number | LBX-T3 |

| Number of working heads | 1PCS |

| Operating station | 4 station |

| Outer diameter of stator | ≤ 160mm |

| Stator inner diameter | ≥ 30mm |

| Transposition time | 1S |

| Adapt to the stator stack thickness | 8mm-150mm |

| Wire package height | 10mm-40mm |

| Lashing method | Slot by slot, slot by slot, fancy lashing |

| Lashing speed | 24 slots≤14S |

| Air pressure | 0.5-0.8MPA |

| Power supply | 380V three-phase four-wire system 50/60Hz |

| Power | 5kW |

| Weight | 1600kg |

Structure

The importance of automatic wire binding machine operation

The automatic wire binding machine is a multifunctional tool with multiple functions such as preset number of turns, automatic stop, forward and reverse winding, and automatic horizontal groove. However, to ensure smooth and safe operation, the following key points need to be considered when using the machine:

One of the basic functions to set up correctly is the start-stop creep function. This feature initiates slow operation after power up to reduce the impact on tensioned structures and enameled wires. According to specific needs, it is recommended to set it between 1 and 3 cycles. In contrast, the slow stop function should be activated at the end of winding to reduce brake shock and thus improve the overall finish of the machine.

Another key consideration is setting parameters based on the operating speed of the device. It is recommended to adjust the parameters to 2~5 turns, and adjust to the wiring winding direction, mainly the displacement and the spindle rotation direction.

In addition, it is also important to connect the wire binding machine correctly. It is recommended to tie the new thread and the old thread immediately after the online is completed, and then manually pull the guide pin before starting. In the automatic working state, avoid placing the limbs between the skeleton groove and the feeding tool to avoid the risk of pinching.

It is best to confirm the wiring path before opening the ceramics to avoid jumping wires in advance. It is necessary to ensure that the tensioner passes through the line once, and manually close the unloading of the clip to pull the line. In case of power failure or emergency stop accident, it must be reset and re-clamped to restart.

Before starting the machine, make sure that power and compressed air are readily available and reset manually only. When operating the transformer coil automatic binding machine, we must pay attention to manual operation, which can greatly reduce failures and improve production efficiency.

Guangdong Zongqi Automation Co., Ltd. is a well-known enterprise specializing in the production of various motor manufacturing equipment, including four-head and eight-station vertical winding machines, six-head and twelve-station vertical winding machines, wire embedding machines, winding embedding machines Wire integrated machine, wire binding integrated machine, rotor automatic line, shaping machine, vertical winding machine, slot paper machine, wire binding machine, motor stator automatic line, single-phase motor production equipment, three-phase motor production equipment. Interested customers can visit their website for more information.