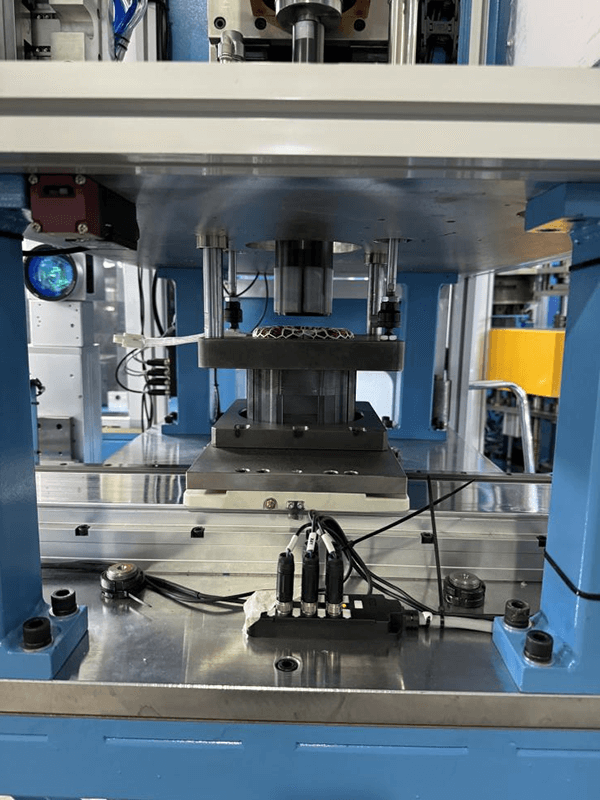

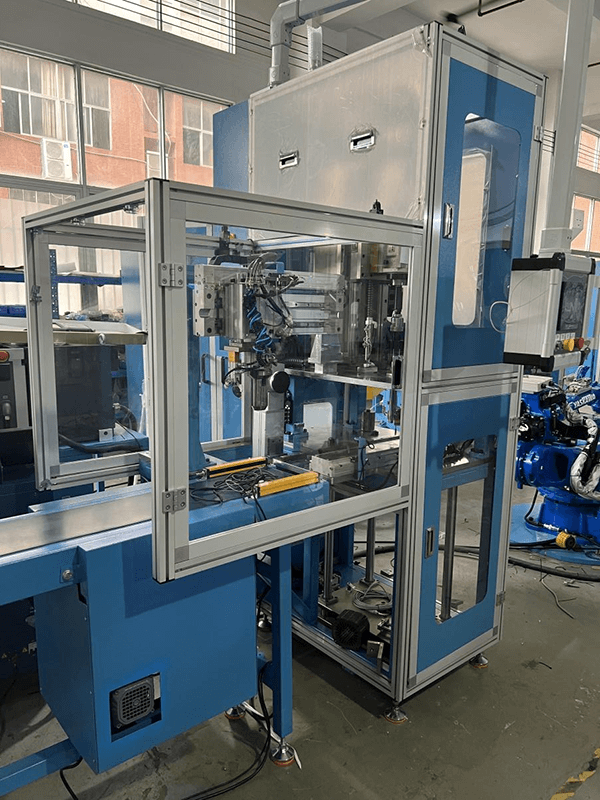

This is newly assembled rolling and expanding groove all-in-one machine.Rolling and expanding is a process after embedding.

Guangdong Zongqi Automation Co., Ltd. , as a high-tech enterprise focusing on the research, development, production, and sales of automation equipment, enjoys a high reputation in the market. In terms of the roller burnishing and slotting machine, Zongqi Automation has demonstrated significant advantages.

The roller burnishing and slotting machine is primarily used for the precision processing of stator slots in the motor manufacturing process, aiming to improve the quality of stator slots, reduce motor noise, and extend the motor's service life. Zongqi Automation's roller burnishing and slotting machine boasts the following product advantages:

High-efficiency processing capability: The roller burnishing and slotting machine adopts advanced numerical control technology, enabling high-speed and high-precision processing. Meanwhile, it is equipped with an efficient tool system, ensuring the durability of tools and processing efficiency. This makes Zongqi Automation's roller burnishing and slotting machine stand out among similar products, significantly improving production efficiency.

Intelligent control: The roller burnishing and slotting machine utilizes an intelligent control system, achieving automated operation and monitoring of the equipment. Through intuitive operating interfaces such as touch screens, operators can easily set processing parameters, monitor the equipment's running status, and adjust processing plans in time. This not only reduces the operational difficulty but also improves processing accuracy and stability.

High-precision processing quality: The roller burnishing and slotting machine ensures the dimensional accuracy and surface quality of stator slots during processing. Zongqi Automation's roller burnishing and slotting machine employs a high-precision positioning system and sensor technology, achieving precise control over tool positions, processing depths, and processing speeds. This guarantees the processing quality of stator slots, improving motor performance and reliability.

Wide applicability: Zongqi Automation's roller burnishing and slotting machine is suitable for processing various types of motor stator slots, including different sizes, shapes, and materials. This makes the equipment have broad application prospects in the motor manufacturing industry, meeting the needs of different customers.

Environmental protection and energy saving: In the design and manufacturing process, Zongqi Automation's roller burnishing and slotting machine fully considers environmental protection and energy saving requirements. The equipment adopts low-noise, low-energy-consumption motors and transmission systems, reducing the noise and energy consumption during operation and minimizing environmental impact.

In summary, Zongqi Automation's roller burnishing and slotting machine exhibits significant product advantages in the motor manufacturing industry due to its high-efficiency processing capability, intelligent control, high-precision processing quality, wide applicability, and environmental protection and energy saving. These advantages make Zongqi Automation's roller burnishing and slotting machine a popular choice for motor manufacturers to improve production efficiency and reduce costs.

Post time: Jul-10-2024