revolution in the stator equipment industry

In recent years, industries around the world have made significant progress, driven by technological breakthroughs that have transformed our lives. One of the areas that has been significantly affected is the stator equipment industry. Stator equipment has undergone a revolution with the introduction of cutting-edge technologies, resulting in improved functionality, efficiency and performance.

The stator device is an essential component of various machines such as electric motors and generators. It is responsible for rotating the fixed parts of the system, generating electromagnetic fields that are critical to the functioning of these devices. Traditionally, stator equipment has relied on conventional designs, limiting its performance and adaptability.

However, with the advent of technological breakthroughs, the stator equipment industry has undergone a paradigm shift. One of the most significant advancements is the development of 3D printing in stator manufacturing. This breakthrough technology enables complex design and precise customization, allowing the creation of stator equipment that perfectly meets specific requirements. Additionally, 3D printing significantly reduces production time and costs, making stator equipment more accessible and affordable than ever before.

Another major technological breakthrough in the stator equipment industry is the implementation of smart sensors integrated with IoT (Internet of Things). By integrating sensors into the stator equipment, manufacturers can monitor and collect real-time data on performance, temperature and vibration. This data enables predictive maintenance, early detection of failures, and optimized operational efficiency. These capabilities are further enhanced by the integration of IoT technology, allowing remote monitoring and control of stator equipment regardless of geographic location.

In addition, advances in materials science are helping to improve stator equipment performance. The development of new materials, such as specialty alloys and composites, allows stator equipment to have greater strength, heat resistance and electrical conductivity. These advancements ensure longevity and reliability, reducing maintenance costs and downtime.

Overall, the introduction of technological breakthroughs in the stator equipment industry has completely changed its landscape. The use of 3D printing, the integration of smart sensors and the Internet of Things, and advances in materials science are taking the functionality and efficiency of stator devices to new heights. This revolution paves the way for a future in which stator devices play a vital role in sustainable energy generation, transportation and industrial applications. As technology continues to evolve, we can only look forward to further innovation and the discovery of new possibilities in this fascinating field.

Common challenges in stator equipment manufacturing

Common challenges in stator device manufacturing arise from traditional methods involving manual production processes. These methods are not only time-consuming, but also labor-intensive and prone to human error. Older manufacturing technologies further exacerbate these issues by limiting the design and functionality of the stator equipment, ultimately compromising performance and efficiency. Therefore, the need for innovative and advanced manufacturing technologies in the stator equipment manufacturing industry has become critical.

Traditional stator manufacturing processes require skilled workers to manually assemble each component. This reliance on manual labor not only increases production time, but also introduces the risk of human error. Each stator is a complex device containing various complex components that require careful alignment. Even the slightest mistakes can lead to inefficiencies and reduced product quality. These challenges are further exacerbated by the lack of consistency in manual labor that makes it difficult to maintain consistency in production batches.

Another significant challenge with conventional stator manufacturing is the limitations imposed by older manufacturing technologies. These technologies often limit the design and functionality of the stator equipment, hindering innovation and reducing overall performance. As technology develops, the demand for more efficient stator equipment continues to increase. However, with traditional manufacturing methods, incorporating new design features and improving performance becomes a significant obstacle.

To address these challenges, manufacturers are increasingly adopting advanced technologies such as automated production processes and computer-aided design (CAD). These innovations revolutionized stator equipment manufacturing by streamlining production, improving consistency, and improving overall product quality.

Automated production processes eliminate reliance on manual labor, allowing for faster and more accurate manufacturing. Advanced machinery and robotics can handle complex assembly tasks with precision, reducing the risk of human error. This not only improves production efficiency but also ensures the consistency and quality of the final product. Manufacturers can now meet customer demands more efficiently and reduce delivery times.

Computer-aided design (CAD) plays a vital role in overcoming the limitations of older manufacturing technologies. With CAD, manufacturers can create and refine stator designs with greater flexibility. This optimizes the performance and efficiency of the stator, thereby improving overall system performance. CAD also enables manufacturers to simulate and analyze the behavior of the stator under different operating conditions, ensuring the design meets the required specifications.

In addition, material advances, such as the use of lightweight and high-performance composites, have made stator equipment not only more efficient, but also more durable and resistant to environmental factors. These materials provide improved electrical insulation properties, reduce losses and increase overall system efficiency.

Advances in Stator Equipment Manufacturing Technology

1.Automation and robotics in stator equipment manufacturing

Automation and robotics have undoubtedly revolutionized manufacturing, and stator equipment manufacturing is no exception. With advances in automation and robotics, modern manufacturing facilities have achieved significant improvements in productivity, efficiency, and overall product quality.

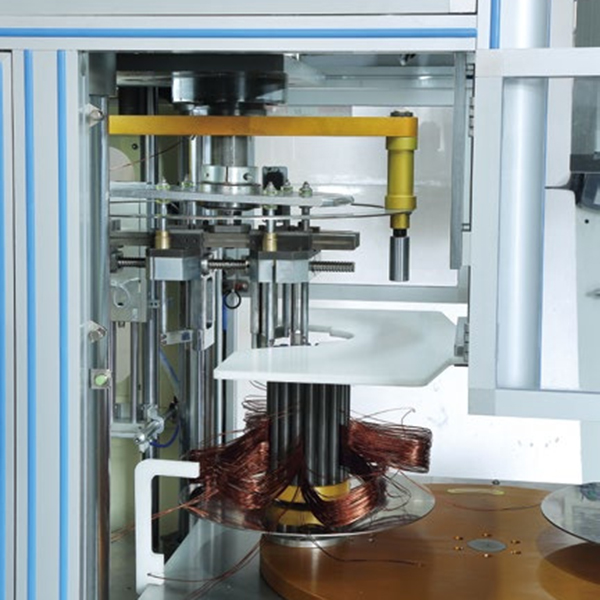

One of the key areas where automation and robotics are having a major impact on stator equipment manufacturing is the coil winding process. The use of robotic winding machines replaces manual labor and enables precise and consistent winding patterns. This ensures a uniform distribution of the electromagnetic field within the stator. This not only improves the performance of the stator equipment, but also reduces the likelihood of failure and increases overall equipment reliability.

Another use of automation and robotics in stator equipment manufacturing is in processes such as lamination and insulation. These tasks require precision and accuracy and can be accomplished more efficiently through automation. The robot is able to deftly handle the stator components and apply the necessary coatings and insulation without human error. This not only improves the quality control of the stator equipment, but also reduces reliance on labor, thereby reducing labor costs.

The adoption of automation and robotics in stator equipment manufacturing has also brought significant benefits to the industry as a whole. First, it significantly increases overall productivity and production speed. Robots can work tirelessly without taking breaks, allowing for a more efficient manufacturing process. Second, automation can perform accurate and repetitive tasks consistently, ensuring high accuracy and minimizing errors. This ultimately improves product quality.

In addition, the integration of automation and robotics in stator equipment manufacturing can lead to cost savings. The initial investment in robotics and automation systems can be large, but in the long run, it can translate into reduced labor costs. By minimizing the need for manual labor and optimizing production efficiency, companies can achieve significant cost savings and improve their competitive advantage.

According to a report by Marketsand Markets, the global manufacturing robot market is expected to be worth US$61.3 billion by 2023. This forecast further highlights the growing importance and adoption of automation and robotics in stator equipment manufacturing. As technology continues to advance, we can expect greater advancements in automation and robotics in this field.

Automation and robotics have brought significant advancements in stator equipment manufacturing. By using robotic winders and automation in processes such as lamination and insulation, manufacturers can improve precision, increase speed, enhance quality control and reduce labor costs. As global manufacturing continues to embrace automation and robotics, stator equipment manufacturers must work to adopt these technologies to remain competitive and meet growing market demands.

2.Advanced Materials in Stator Equipment Manufacturing

Advanced materials have transformed the world of stator equipment manufacturing, revolutionizing the way these important electrical components are produced. The integration of materials such as advanced polymers, composites and high-performance laminates has a profound impact on the durability, thermal resistance and mechanical strength of stator equipment.

One of the most significant benefits of using advanced materials in stator equipment manufacturing is increasing the overall efficiency of these components. With the introduction of lightweight and highly permeable materials, the performance of stator equipment has been greatly enhanced. Not only do these materials allow for more efficient energy transfer, but they also help reduce losses within the system.

In recent years, advances in nanotechnology have further promoted the development of nanocomposite materials for stator windings. These nanocomposites have excellent electrical and thermal conductivity, resulting in increased power density and reduced losses. As power density increases, stator equipment becomes more compact and efficient, resulting in cost savings for manufacturers and improved system performance.

The integration of advanced materials in stator equipment manufacturing also enables manufacturers to create more durable and reliable products. For example, high-performance laminates offer excellent wear resistance, ensuring that stator equipment can withstand the harsh conditions in which it is regularly operated.

In addition, these advanced materials play a vital role in improving the safety of stator equipment. The use of advanced polymers and composites helps enhance insulation properties, prevent leakage and reduce the risk of accidents.

Companies specializing in the manufacture of stator equipment are embracing advanced materials, recognizing their potential for innovation and efficiency. By incorporating these materials into the manufacturing process, they are able to create stator devices that are not only efficient but also meet the demanding requirements of modern industry.

The integration of advanced materials in stator device manufacturing has revolutionized the field. These materials, such as advanced polymers, composites and high-performance laminates, offer greater durability, heat resistance and mechanical strength. In addition, the use of lightweight, highly permeable materials significantly increases overall efficiency. As nanotechnology continues to advance, manufacturers are now able to develop nanocomposites for stator windings, further increasing power density and reducing losses. As a result, stator equipment has become more compact, efficient and cost-effective, providing a range of benefits to manufacturers and industry. By adopting these advanced materials, companies in the stator equipment manufacturing industry are poised for continued growth and innovation.

3.Virtual Design & Prototyping: A Game Changer for Stator Equipment Development

Virtual design and prototyping technology has revolutionized the product development process for stator equipment. In the past, manufacturers had to rely solely on physical prototypes to test their designs, which was time-consuming and expensive. However, with the advent of virtual simulation and digital prototyping, manufacturers are now able to optimize designs, detect potential defects and improve product performance before actually producing the device.

Virtual design and prototyping software allows manufacturers to create digital replicas of stator equipment, complete with detailed specifications and components. This digital model can be manipulated and analyzed to identify any potential issues or areas for improvement. By conducting virtual simulation, manufacturers can test the performance and reliability of stator equipment under various operating conditions to make informed design decisions.

One of the main advantages of virtual design and prototyping is the ability to detect potential defects early in the development process. By simulating the performance of the stator equipment, manufacturers can identify any weak points or stress points that could lead to failure or defects. This allows them to make design modifications or select alternative materials to improve overall product quality and durability.

In addition, virtual design and prototyping technology allows manufacturers to optimize designs to improve performance and efficiency. By simulating equipment in a virtual environment, manufacturers can quickly evaluate different design options and determine the best configuration. This helps reduce the number of physical prototypes required and saves significant time and cost in the development process.

In addition to design optimization, virtual design and prototyping can also help improve product performance. By simulating the behavior of stator equipment under different operating conditions, manufacturers can identify potential performance bottlenecks and make necessary adjustments to improve product efficiency and functionality. This ensures that the final product meets or exceeds required performance requirements.

Additionally, virtual design and prototyping technologies enable manufacturers to effectively communicate their design intentions to stakeholders such as customers, suppliers, and regulatory agencies. Detailed digital models enable clear visualization and demonstrate how the stator device functions in a real-life scenario. This helps gain stakeholder buy-in and ensures the final product meets their expectations.

Virtual design and prototyping bring significant advancements to the product development process for stator equipment. The ability to optimize designs, detect potential defects and improve product performance before actual production saves manufacturers time and costs. Virtual design and prototyping technology has become an indispensable tool in the industry, allowing manufacturers to develop high-quality stator equipment that meets or exceeds customer expectations.

4.Maximizing Efficiency: How Sensor Tech Impacts Stator Mfg

Sensor technology in stator equipment manufacturing Sensor technology plays a key role in stator equipment manufacturing, enabling real-time monitoring, fault detection and predictive maintenance.

By embedding sensors in the stator windings and other components, manufacturers can continuously monitor critical parameters such as temperature, vibration and insulation condition. These sensors provide valuable insights into stator health and performance, enabling proactive maintenance and reducing unplanned failures.

In the world of stator equipment manufacturing, maintaining optimal performance and preventing unexpected failures is crucial. Stators are critical components in various industries, including power generation, industrial machinery and transportation systems. These machines often operate in harsh environments and are subject to high temperatures, vibrations and electrical loads. Stator failure can lead to costly downtime, lost production and safety hazards.

Traditional maintenance methods rely on regular inspections and reactive repairs. However, this approach is often inefficient and ineffective. It does not provide real-time information about the health of the stator, making it difficult to identify potential problems before they escalate. This is where sensor technology comes into play.

By embedding sensors throughout the stator and connecting them to systems that collect and analyze the data, manufacturers can gain a complete picture of the condition of the stator. For example, temperature sensors can monitor hot spots and detect abnormal temperature rises, indicating potential insulation degradation or cooling system failure. Vibration sensors can detect excessive vibration, which can be a sign of misalignment, bearing wear or structural problems. Insulation condition sensors monitor the health of the insulation, alerting manufacturers of potential failures or breakdowns.

With real-time monitoring capabilities, manufacturers can detect early warning signs of potential problems, allowing for timely maintenance intervention. By resolving issues promptly, manufacturers can prevent unexpected failures, reduce downtime and extend the overall service life of their stator equipment. Additionally, data collected from sensors can be used to optimize maintenance plans, ensuring efficient and effective allocation of resources.

Additionally, sensor technology enables predictive maintenance, anticipating potential failures and taking proactive steps to prevent them. By analyzing the data collected from sensors, manufacturers can identify patterns and trends that indicate potential future problems. With this knowledge, manufacturers can plan ahead, order necessary replacement parts, and schedule maintenance activities during planned downtime.

Sensor technology has revolutionized stator equipment manufacturing by providing real-time monitoring, fault detection and predictive maintenance capabilities. By continuously monitoring key parameters such as temperature, vibration and insulation condition, sensors embedded in the stator can provide valuable insights into its health and performance. This enables manufacturers to take proactive maintenance measures, reduce unplanned failures and optimize overall equipment performance. With sensor technology, stator equipment manufacturing has entered a new era of efficiency, productivity and reliability.

Conclusion

Technological advances in stator equipment manufacturing are changing the industry. Automation and robotics increase precision and efficiency, while advanced materials enhance durability and performance. Virtual design and prototyping have revolutionized the product development process, while sensor technology enables real-time monitoring and predictive maintenance. Adopting these advancements not only improves the quality and reliability of stator equipment but also enables manufacturers to meet the changing needs of various industries. Through continued research and development, stator equipment manufacturing has greater potential for innovation in the future, thereby driving progress in renewable energy, transportation and other fields.

Guangdong Zongqi Automation Co., Ltd. mainly produces motor manufacturing equipment, integrating R&D, manufacturing, sales and after-sales. Zongqi people have been deeply involved in motor automation manufacturing technology for many years, and have a deep understanding of motor-related application manufacturing technology, and possess professional and rich experience .

Our company's products and production lines are applied to home appliance, industry, automobile, high-speed rail, aerospace etc motor field widely. And the core technology is in the leading position.And we are committing to providing customers with all-round automated solutions of AC induction motor and DC motor’s manufacture.

Feel free to contact us anytime! We're here to help and would love to hear from you.

Address : Room 102, Block 10, Tianfulai International Industrial City Phase II, Ronggui Street, Shunde District, Foshan City, Guangdong Province

Whatsapp / Phone : 8613580346954

Email: zongqiauto@163.com

Post time: Oct-19-2023