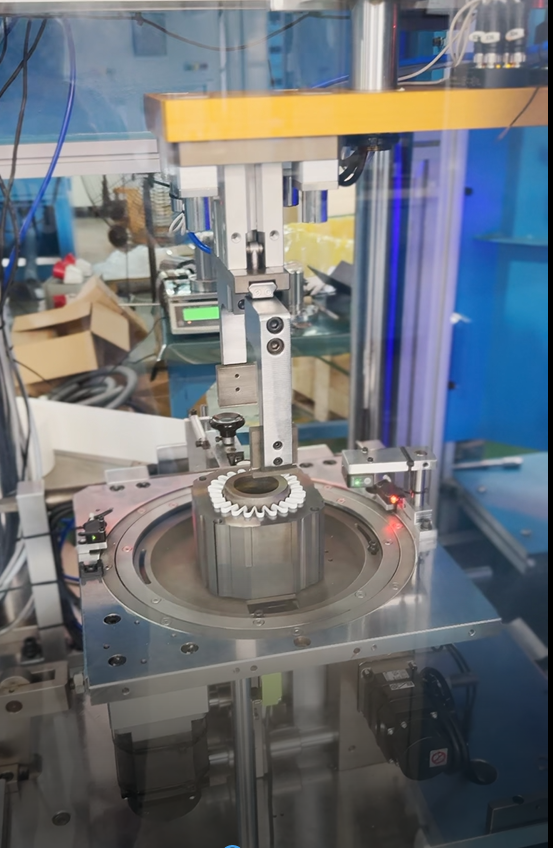

The paper inserting machine is a crucial equipment in the production process of electric motors, primarily used for inserting insulating paper into the stator slots of electric motors. This step is vital for the performance and safety of electric motors, as it directly affects the insulation effect and operational efficiency of the motors. By automating this process, the paper inserting machine significantly enhances the efficiency and accuracy of motor production.

Features of Zongqi Automation’s Paper Inserting Machine

High Precision: Zongqi Automation’s paper inserting machine employs advanced control systems and precise mechanical structures to ensure that insulating paper is accurately inserted into stator slots, meeting the high precision requirements of motor production.

High Efficiency: The paper inserting machine boasts high-speed, continuous operation capabilities, significantly boosting the efficiency of motor production. Additionally, it can be integrated with other automated equipment (such as winding machines, shaping machines, etc.) to form a complete automated production line.

Ease of Operation: Zongqi Automation’s paper inserting machine is designed with a user-friendly human-machine interface, allowing operators to easily initiate, stop, and set parameters for the equipment. Furthermore, the machine is equipped with comprehensive fault alarm and diagnostic functions, facilitating maintenance personnel to quickly locate and resolve issues.

Excellent Stability: The paper inserting machine is manufactured using high-quality components and materials, ensuring excellent durability and stability. It maintains consistent performance output in long-duration, high-intensity working environments.

Application of the Paper Inserting Machine in Automated Production Lines

In Zongqi Automation’s automated motor production line, the paper inserting machine is typically used in conjunction with other automated equipment to form a complete production line. This production line automatically completes processes such as motor winding, paper insertion, shaping, and wire binding, greatly enhancing motor production efficiency and product quality.

The position and role of the paper inserting machine in the production line are crucial. It is positioned after the winding machine, responsible for inserting insulating paper into the stator slots that have already been wound. Once this step is completed, the stator can proceed to the next stages of winding and wire embedding. Automated operation of the paper inserting machine not only improves production efficiency but also reduces errors and safety hazards associated with manual operation.

Post time: Nov-11-2024