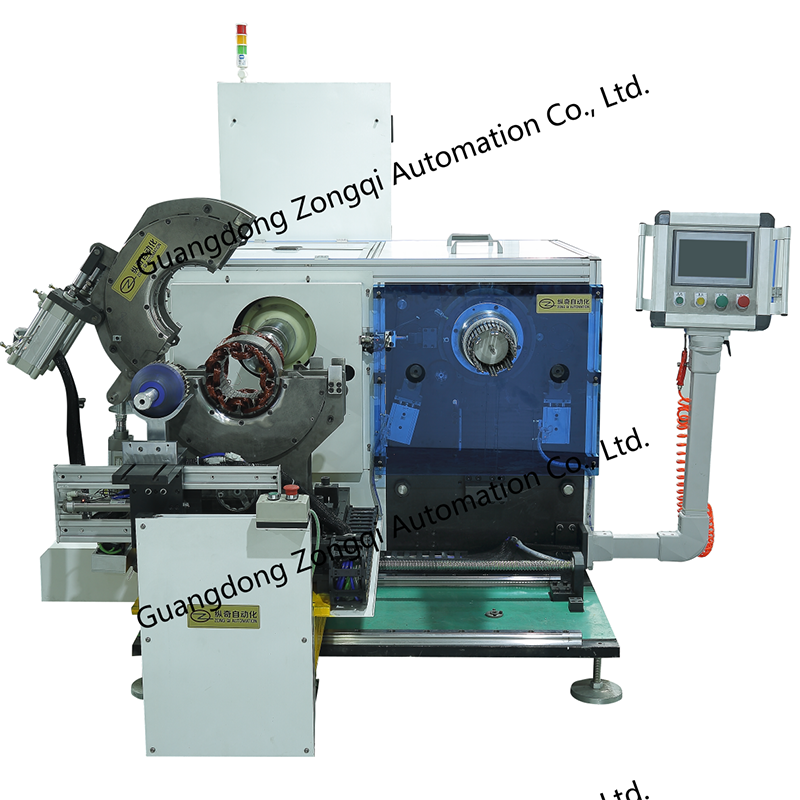

Guangdong Zongqi Automation Co., Ltd. has significant product advantages in the field of wire inserting machines, which are directly reflected in various aspects of the wire inserting machines. The following are the advantages of the good wire inserting and shaping machines summarized by the company:

High Automation and Production Efficiency:

The wire inserting and shaping machine integrates double-sided binding, knotting, automatic thread cutting and suction, finishing, and automatic loading and unloading,achieving a high level of automated operation.

By means of the fully automated process, this machine can greatly improve production efficiency, enabling one person to complete the work of more than ten people in the past, thus reducing enterprise costs.

Precise Control and High Quality:

The binding and shaping machine can precisely adjust parameters such as wire winding speed, number of ties, and time through the PLC controller, ensuring precise control of the production process.

This precise control ensures the accuracy and stability of the wire inserting process, thus improving the quality of the product.

Diversity and Flexibility:

It features fast speed, high stability, accurate positioning, and rapid mold change.

The machine can also be designed as a multi-head and multi-station wire winding and inserting machine according to customer needs, such as one-winding-one-inserting and two-winding-two-inserting, to meet different production needs.

Energy Saving and Environmental Protection:

The wire inserting and shaping machine adopts energy-saving design, saving electric energy and reducing production costs.

At the same time, due to its high degree of automation, it reduces manual operation, decreases energy consumption and emissions during the production process, making it more environmentally friendly.

Reliability and Stability:

The binding and shaping machine using the unique patented design of the double track cam, it does not hook the grooved paper, does not hurt the copper wire, lint-free, does not miss the tie, does not hurt the tie line and the tie line does not cross.

Simple Operation and Easy Maintenance:

The machine is easy to debug, user-friendly, and has a reasonable mechanical structure design.

At the same time, the design of the machine takes into account ease of maintenance, making equipment maintenance and care simpler and more convenient.

In summary, Guangdong Zongqi Automation Co., Ltd.'s wire inserting and shaping machine possesses significant advantages in the motor manufacturing field due to its high automation, precise control, diversity and flexibility, energy saving and environmental protection, reliability and stability, as well as simple operation and convenient maintenance.

Post time: May-29-2024