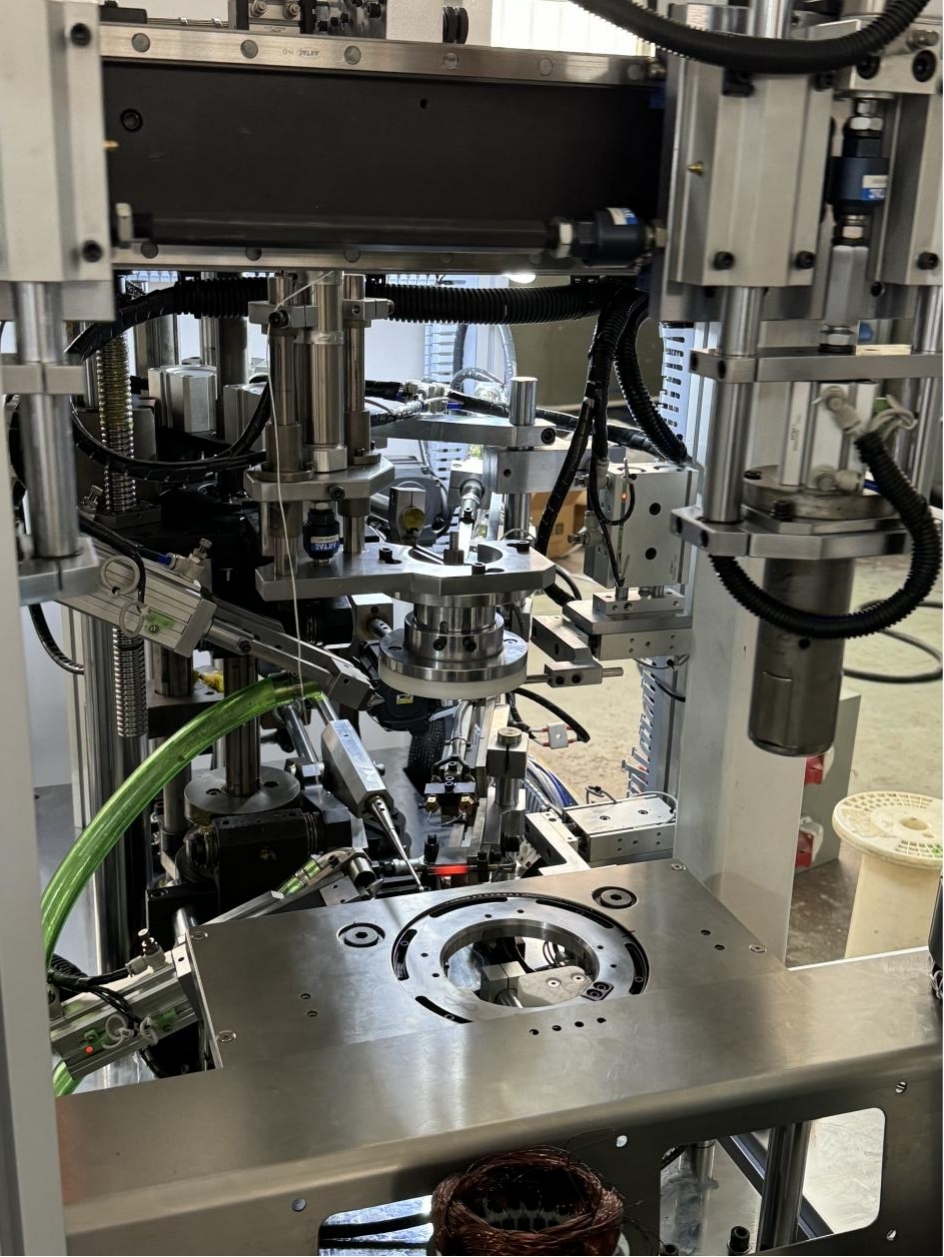

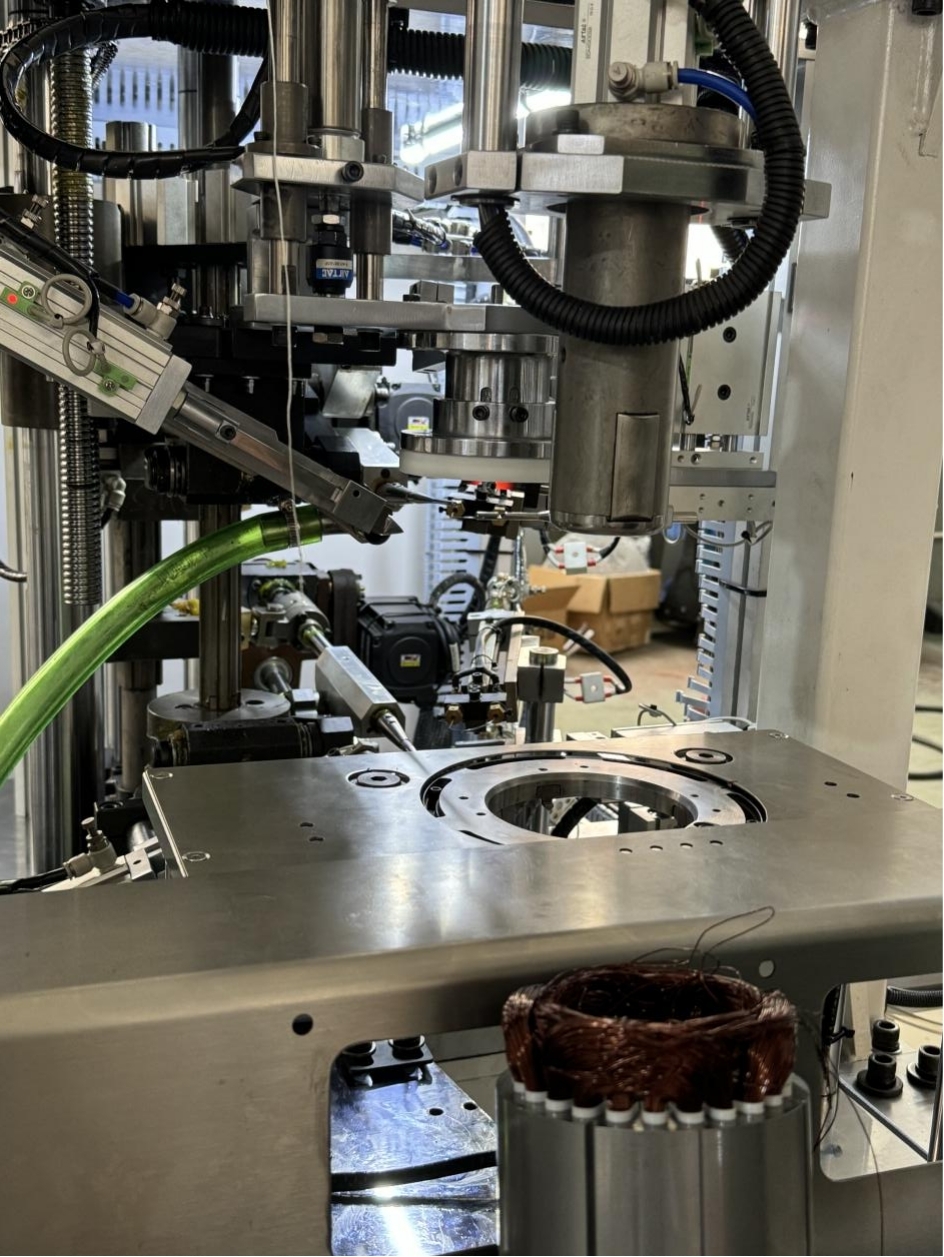

It was just assembled yesterday, and it's the binding machine that is being adjusted today.The binding machine is the final process of the automatic line.

The machine adopts the design of entering and exiting stations; it integrates double-sided binding, knotting, automatic thread cutting and suction, finishing, and automatic loading and unloading.

It has the characteristics of fast speed, high stability, accurate position and quick mold change.

This model is equipped with automatic loading and unloading device of transplanting manipulator, automatic thread hooking device, automatic knotting, automatic thread trimming, and automatic thread suction functions.

Using the unique patented design of the double track cam, it does not hook the grooved paper, does not hurt the copper wire, lint-free, does not miss the tie, does not hurt the tie line and the tie line does not cross.

The hand-wheel is precision-adjusted, easy to debug and user-friendly.

The reasonable design of the mechanical structure makes the equipment run faster, with less noise, longer life, more stable performance, and easier to maintain.

Post time: Jun-25-2024