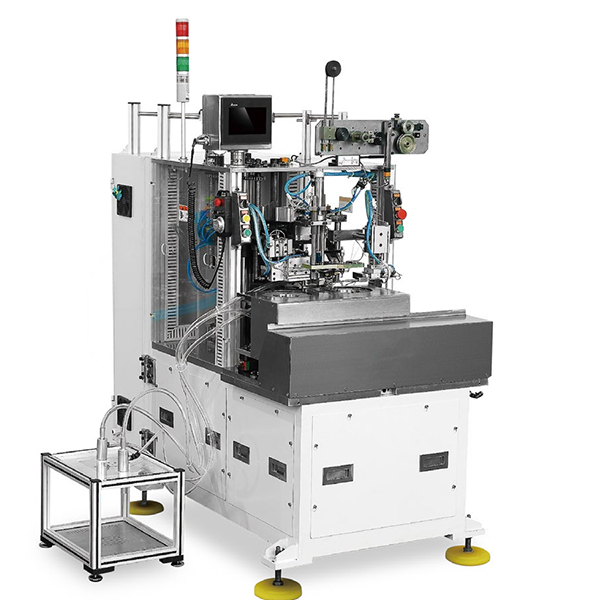

Motor Manufacturing Made Easier with Servo Binding Machine

Product Characteristics

● CNC7 axis CNC system of machining center is used to control and cooperate with man-machine interface.

● It has the characteristics of fast speed, high stability, accurate position and rapid die change.

● The machine is equipped with automatic adjusting stator height, stator positioning device, stator pressing device, automatic wire feeding device, automatic wire shearing device, automatic wire suction device and automatic wire breaking detection device.

● The left and right mobile working platform saves the time of putting the stator in automatic operation, thus greatly improving the overall efficiency.

● This machine is especially suitable for the binding of long lead motors and the automation of the production line of long lead motors.

● This machine is also equipped with automatic hook tail line device, which has the functions of automatic knotting, automatic cutting and automatic suction.

● The unique patented design of double-track cam is adopted. It does not hook and turn slot paper, damage copper wire, no hair, no missing binding, no damage to tie wire and no crossing of tie wire.

● Automatic refueling system control can ensure the quality of equipment ever more.

● Hand wheel precision adjuster is easy to debug and humanized.

● Reasonable design of mechanical structure can make the equipment run faster, noise less, work longer, performance become more stable and easier to maintain.

Product Parameter

| Product number | LBX-02 |

| Number of working heads | 1PCS |

| Operating station | 2 stations |

| Outer diameter of stator | ≤ 160mm |

| Stator inner diameter | ≥ 30mm |

| Transposition time | 0.5S |

| Adapt to the stator stack thickness | 8mm-150mm |

| Wire package height | 10mm-40mm |

| Lashing method | Slot by slot, slot by slot, fancy lashing |

| Lashing speed | 24 slots≤14S |

| Air pressure | 0.5-0.8MPA |

| Power supply | 380V three-phase four-wire system 50/60Hz |

| Power | 4kW |

| Weight | 1100kg |

Structure

The working principle and characteristics of the wire binding machine

The wire binding machine is an essential tool for the production of various motors. This machine significantly reduces the labor intensity of workers, improves production efficiency and reduces production and operation costs. Hence, implementing this machine can increase the profits of the company.

There are two types of wire binding machines: single-sided and double-sided. The single-sided machine only uses one crochet hook, while the double-sided machine uses one hook for the upper and lower hooks. Both machines are efficient and durable, with unique features. They work the same way.

The basic working principle of the wire binding machine involves several key components. First of all, the rotation of the camshaft drives the whole machine to run. Then, the dead crochet hook moves back and forth up and down to thread the binding.

Proper attention and maintenance are essential to optimal performance of your wire binding machine. Proper maintenance can improve the service life and work efficiency of the machine.

To ensure robust performance, the wire binding machine has several features, including:

1. Widely used in electronics, digital, mobile phones, automobiles and other industries.

2. High-precision servo motor is adopted, and the torsion angle is more precise.

3. The mechanical structure design is optimized, the overall mechanical performance is improved, and repeated positioning errors are further reduced.

4. Using advanced manufacturing technology, the wiring is stable, reducing disconnection and displacement.

Guangdong Zongqi Automation Co., Ltd. specializes in the production of motor manufacturing equipment. The company integrates research and development, manufacturing, sales and after-sales. They have a wide range of products such as wire binding machines, single phase motor production equipment, three phase motor production equipment, etc. After years of creating an efficient marketing system, the company has established an effective marketing network and high-quality customer service. They look forward to working with you.