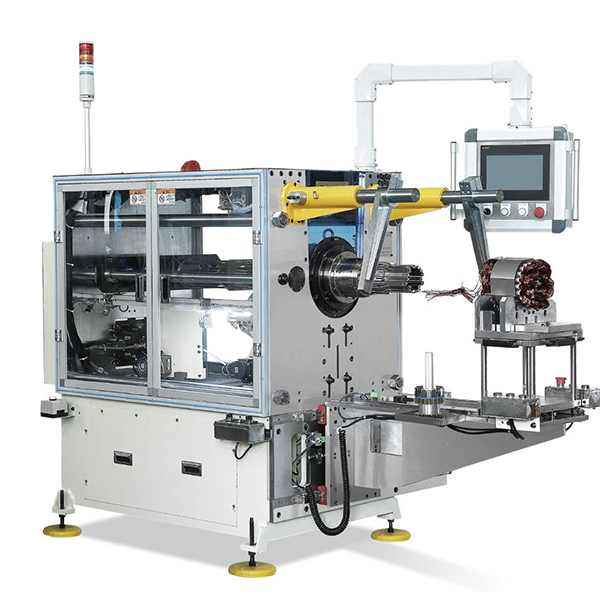

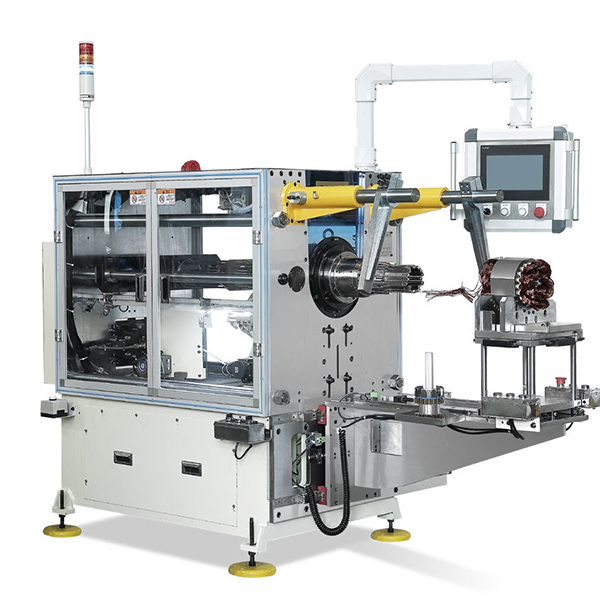

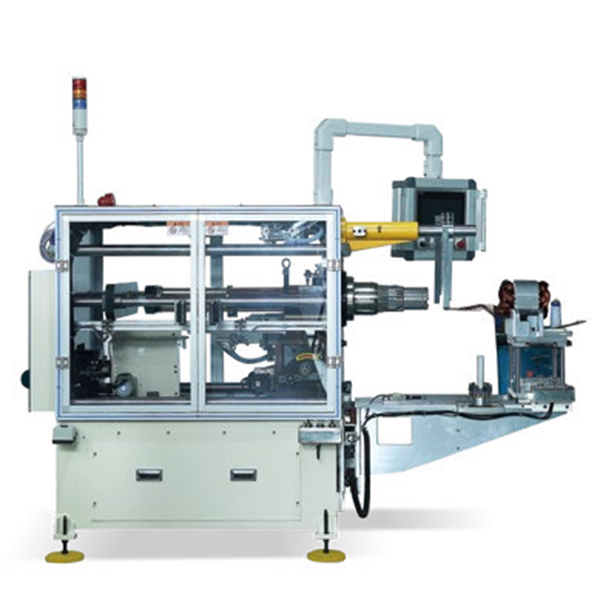

Horizontal Full Servo Embedding Machine

Product Characteristics

● This machine is a horizontal full servo wire inserting machine, an automatic device that automatically inserts coils and slot wedges into stator slot shape; this device can insert coils and slot wedges or coils and slot wedges into stator slot shape at one time.

● Servo motor is used to feed paper (slot cover paper).

● The coil and slot wedge are embedded by servo motor.

● The machine has the function of pre-feeding paper, which effectively avoids the phenomenon that the length of the slot cover paper varies.

● Equipped with human-machine interface, it can set the number of slots, speed, height and speed of inlaying.

● The system has the functions of real-time output monitoring, automatic timing of single product, fault alarm and self-diagnosis.

● The insertion speed and wedge feeding mode can be set according to the slot filling rate and the type of wire of different motors.

● Conversion of production can be achieved quickly with the change of die, and the adjustment of stack height is convenient and fast.

● With the configuration of 10 inch large screen makes operation more convenient.

● It has wide application range, high automation, low energy consumption, high efficiency, low noise, long service life and easy maintenance.

● It is particularly suitable for the insertion of gasoline generator motor, pump motor, three-phase motor, new energy vehicle drive motor and other large and medium-sized induction motor stator .

Product Parameter

| Product number | WQX-250 |

| Number of working heads | 1PCS |

| Operating station | 1 station |

| Adapt to the wire diameter | 0.25-1.5mm |

| Magnet wire material | Copper wire/aluminum wire/copper clad aluminum wire |

| Adapt to the stator stack thickness | 60mm-300mm |

| Maximum stator outer diameter | 260mm |

| Minimum stator inner diameter | 50mm |

| Maximum stator inner diameter | 187mm |

| Adapt to the number of slots | 24-60 slots |

| Production beat | 0.6-1.5 seconds/slot (printing time) |

| Air pressure | 0.5-0.8MPA |

| Power supply | 380V three-phase four-wire system 50/60Hz |

| Power | 4kW |

| Weight | 1000kg |

Structure

Full thread machine speed mode

Thread embedding machines revolutionized the production process by introducing automation. However, this level of automation requires highly skilled operators to operate the machines with precision. The machine is equipped with automatic spindle speed control function, which makes it easier to adjust the speed during operation. There are different types of thread embedding machines on the market, each with different configurations.

The most commonly used spindle motors for thread embedding machines are AC motors, DC motors and servo drive motors. These three types of motors have unique features in terms of speed controllers. In this article, we will discuss how the full line of motor models of these motors are regulated.

1. AC motor speed regulation mode: AC motor does not have speed regulation function. Therefore, to regulate the speed, a solenoid control or drive must be installed. Winding equipment inverters are a popular solution that allow the equipment's control system to function as a speed controlled variable frequency motor. This speed regulation method also contributes to energy saving.

2. Servo drive motor speed regulation mode: The wire inserting machine is a precision moving part in high-precision winding equipment. It requires a special drive system combined with the machine to achieve closed-loop operation control. The prominent features of the wire inserting machine engine are constant torque and closed-loop operation, which are specially designed to meet the processing requirements of precision coils.

To sum up, choosing the appropriate speed regulation method depends on the type of motor used in the thread embedding machine. The correct configuration helps optimize productivity while meeting precision manufacturing standards.